Shuttle with operator on board

Unlike the battery powered shuttle, it features a standard power cable, normally combined with a cable trolley to avoid tangling.

Suitable for medium distances and semi-automated solutions with an operator managing the loading and unloading on roller conveyors from the shuttle’s platform.

Also suitable for use in more automated systems.

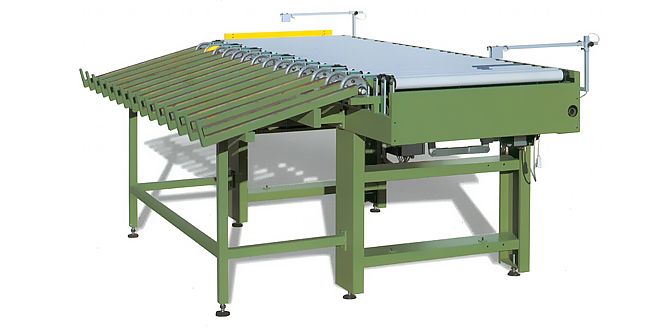

Roller and belt conveyors

Ideal to load and unload machines, especially when 90° rotations need to be done in limited space.

Belt conveyors

Perfect for light duty and materials with a very small surface usable for transport. Ideal for boxes, packages, small size finished materials or items with an irregular bottom surface. Less versatile than roller conveyors, they are commonly used for long distance transfers. Inclined conveyors – that use special grip-faced belts or belts with strips of PVC – are available to accommodate ascending transfers.

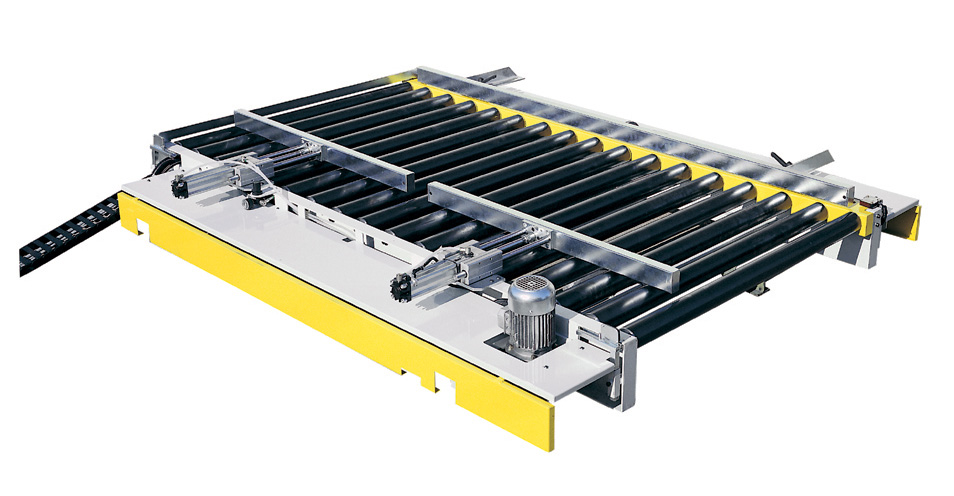

Motorised Roller Conveyors

Practical and versatile, motorised roller conveyors adapt to every need. Ideal to transport items with an irregular bottom surface, with chain or slat transmission, can be used for light or heavy duty, long or short distances, and feature basic or complex automation, for machine loading and unloading or accumulation.

Trolleys

Hand trucks that can be moved freely without track constraints. The fact that they do not require tracks makes them a useful and versatile choice in departments with limited space and many off-line processes. A mechanical locking system of the rollers stops transported materials from overturning.

Item Turners

Placed along idle roller conveyor lines, they are used to rotate material and are especially useful to prepare for the next department or manufacturing stage. They can also be used to rotate items 90° and continue along the line if limited space does not allow the use of curves.

Cart-on-track Conveyors

Ideal to manage department workflows. A single cart can feed multiple roller conveyors, even across departments located far from each other. They can have fixed or rotating platforms.

Idle rollers and curves

Ideal for medium loads, idle rollers and curves can be used to move materials at ground or working height, depending on whether they are transporting piles of materials or final products.

Multidirectional lifting platforms

As an alternative to the revolving table, we produce fixed or retractable ball coveyors, roller and packrail platform to reduce space or to move goods in multiple directions

Lift tables with motorized rollers

This type of lift is ideal when loading and unloading requires motorised roller conveyors. In this case also the table can be fitted with an automated system to create a single system for transport, loading, work processing, and unloading.

Lift tables with idle roller tops

Useful to lift and lower goods from roller conveyors, from ground or higher heights. If the rollers are on a ground level conveyor and the production cycle doesn’t require rollers at any other height, the platform is made with idle rollers that “retract” (when the lift rises above the minimum height, the rollers retract turning the platform in a simple metal top, much safer, to prevent the movement of materials during lifting). We also make platforms with idle rollers and pneumatic lock and platforms with rollers that turn 180°.

Lift tables with metal tops

Can be used as worktops as well as for loading and unloading, can be customised with recesses for forklifts, with side stops or semi-automatic systems (useful when used for loading and unloading from other machines). Like product turners, lift tables are equipped with a material turning electro-hydraulic system.

Off-line turners

To turn materials on a side and off the incoming line. Used specifically to continue the journey on a different line or as a terminal.

Packaging turners

The rollers retract to allow operators to close and finish packing. Once the operation is finished, the material can be repositioned on the rollers and continue its journey along the line.

Shuttle without operator on board

Suitable for short distances, doesn’t have an operator on board because normally its work can be controlled from a workstation.

a batteria_1.jpg)

Battery powered shuttle

The total absence of power cables connected to the shuttle is certainly the most convenient feature. Normally, this type of product is combined with the platform for the on-board operator and automation systems to load and unload production lines.

It’s the most suitable product for fully automated systems, with or without operator, and with automated and semi-automated processes.

The battery size is scaled according to the number of work shifts required