Motorised Conveyors

Motorised conveyors help reduce the need for operators to move to a minimum, allowing them to remain at their workstations while materials move on to the next production process, machine, or department.

Motorised conveyors are machines that transfer, accumulate and/or distribute goods from one place to another. They may connect two warehouses or two departments, a warehouse and a production area, or two areas in the same department, making transfers flawless, reducing internal transport time, and increasing productivity.

Especially suitable for long distances, but extremely versatile because different solutions can be created based on specific production requirements.

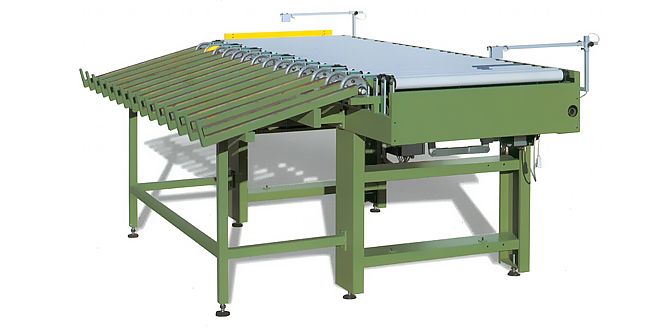

Roller and belt conveyors

Ideal to load and unload machines, especially when 90° rotations need to be done in limited space.

Belt conveyors

Perfect for light duty and materials with a very small surface usable for transport. Ideal for boxes, packages, small size finished materials or items with an irregular bottom surface. Less versatile than roller conveyors, they are commonly used for long distance transfers. Inclined conveyors – that use special grip-faced belts or belts with strips of PVC – are available to accommodate ascending transfers.

Motorised Roller Conveyors

Practical and versatile, motorised roller conveyors adapt to every need. Ideal to transport items with an irregular bottom surface, with chain or slat transmission, can be used for light or heavy duty, long or short distances, and feature basic or complex automation, for machine loading and unloading or accumulation.